So my wonderfully patient Bride often agrees to humor me and

my attempts at woodworking. Thus far, my resume only included building a

bookshelf for our living room, which she graciously rearranged the living room

to accommodate. The bookshelf worked out ok, although the finished product

ended up much larger than I had first envisioned. Apparently I dream big and

produce even bigger, which can be a good thing at work, but not so great when

you are trying to fit the results into a 12x14 room.

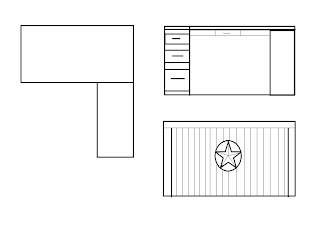

Once the drawing was complete, I made a trip to the Lowe’s store in Conroe where I bought all of the lumber and stain, then a short jog

out to RND Rustics in Magnolia, TX, where I bought the cast iron stars for

trim. The lumber list consisted of

whitewood dimensional lumber: (3) 1x10x6, (16) 1x4x10, and (3) 2x6x10 treated

lumber for strength. Every cut was measured three times before the trusty Ryobi

circular saw was even triggered, then measured again after the cut was made.

The desk top was fashioned from the 1x10 boards glued edge

to edge, with ½” dowels every 6” for added strength, then clamped in a pair of

pipe clamps overnight to dry (Thank you Aunt Judy and Uncle Jim, for selling

those wonderful devices. I KNEW they would come in handy).

As the top cured, I began building the legs of the desk by

gluing and screwing four 1x4’s together in a square tube 36” tall. My bride

asked me “Isn’t that going to make the desk kinda tall”, to which I replied

that it was. Since I’m 6’02” I figured the desk should be taller than average

to accommodate my height, not to mention the fact a taller desk seems quite

regal, like a judge on the bench…

Once the legs dried and were ready to be assembled I

toenailed the 2x6 boards to the inside of the legs and checked everything for

square for the first time. (I know, seems kinda late at that point, but it was

actually dead on, so maybe not)

While waiting on the leg structure to cure I began sanding

the desk top, starting with an 80 grit to remove all of the rough edges, then

used a 120 grit, 160 grit, and finished with a 220 grit for a smooth finish

that still left some of the rustic look (read defects in the wood…) without having

to worry about splinters. I also cut twenty 30” pieces of 1x4 to use as trim

and sanded it the same way as I did the top. By the time all of the sanding was

finished the top and legs were ready to assemble, which I did by screwing a 1 ½

inch triangle cut piece of wood to the legs, then to the desk top. (Proof that

I’m not a carpenter…I know there’s a name for those “triangles” but I can’t

remember it; An example of knowledge in practice but not in theory!)

With the top installed, I used a countersink drill bit and

wood screws to attach the trim pieces and a curtain to three sides of the desk,

which made it actually look like a piece of furniture rather than a work bench

and a collection of wood.

I

was finally ready to stain the desk. I used an oil based Cordovo stain in

English oak to give me a color somewhat darker than the natural whitewood as

well as to bring out the natural beauty of the pine knots. Rather than follow

the directions, which was to brush the stain on and then almost immediately

wipe it off, my Darlin and I brushed the stain on and made sure all of the

stray brush marks and bubbles were out, and then let it dry. I made this

decision after experimenting with several methods of applying the stain,

sanding, and re-staining on a scrap piece. Needless to say, the color came out

exactly as I had hoped.

The final touch was to add the cast iron stars from RND

Rustics. The smaller stars are attached by a nail made to the rear of the star,

and the larger center star is attached by wood screws on either side. This was

a fun project that turned out almost exactly like the plans I had drawn out.

Considering I am neither an artist (I couldn’t draw flies if

I were covered in poo) nor a carpenter, I am pretty happy with the results. I

attribute the success of this project to my beautiful wife, whose suggestion to

take my time and “do it right” was instrumental in the outcome, as well as her

willingness to wrangle our urchins while I stayed in the garage working on it.

As a side note, it’s amazing how little you can hear in the garage when a circle

saw is slicing through a 2x8. It’s even more amazing what you can hear when it

stops, such as “Stop putting your chicken on that scab”, and “Monkey! Stop

drinking the dogs’ water”. With such jewels as that being common fare at our

house, I think it may be time for another project. Maybe new furniture for the

whole house? Just kidding Sweetheart. I

couldn’t do that to you……

As a side note, the guys at work all asked me the same question my loving wife did.... Isn't it too tall, or is that a bar? Maybe I am spending a bit too much time at work...they're starting to sound familiar.

Until next time,

It is a desk! Wow! I'm impressed! What an awesome job! You really bought that right ?

ReplyDeleteNo ma'am, I made it with my own two paws. I've had to show the "in progress photos to several here at the office because they think I bought it.

ReplyDeleteOnly a man of your profession would make sure he had the trail of evidence! Its not trail! What's the word I cant think of due to loss of years...

ReplyDeleteIt's all about the documentation!

ReplyDeleteGreat Job Paul!

ReplyDelete